Improving asset traceability at Rockfon with IFS Ultimo EAM

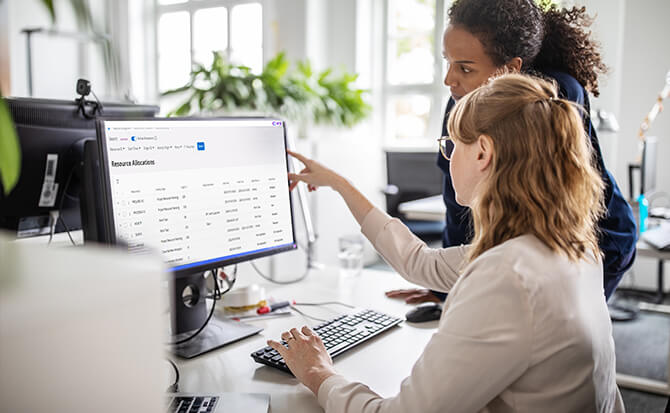

As part of Rockfon’s efforts to modernize its manufacturing facility, it looked for an EAM system to gain better visibility over its maintenance operation, improve traceability, and enhance communication.

The company chose IFS Ultimo. The IFS Ultimo EAM solution was already successfully used by its sister factory in Belgium, and its high level of customizability made it a good fit for Rockfon’s unique operating environment.

To learn more, read this customer story.

IFS Ultimo has helped break down silos in our organization. We are now one team, the software helps us all work better together.

About Rockfon

Part of the global ROCKWOOL Group, Rockfon is a leading provider of stone wool acoustic ceilings and wall solutions, including acoustic ceiling tiles, wall panels, and suspended ceiling grids. Its site in Chicago specializes in manufacturing metal ceiling panels and Chicago Metallic® ceiling suspension grid systems using roll-forming.

Benefits of IFS Ultimo:

- Better communication between teams

- Immediate access to critical data in digital format

- Elimination of human error in record keeping

- Improved safety across the facility